Mobile Accessories Product Development, Mobile Phone Accessories Product Design, Electronic Design for Mobile Accessories

Written by Electronic Desgin Engineering Product DevelopmentMobile Accessories Product Development

Advertising Player Product Development, Electronics Product Development in China, Advertising Video Player

Written by Electronic Desgin Engineering Product DevelopmentAdvertising Player Product Development content coming soon.

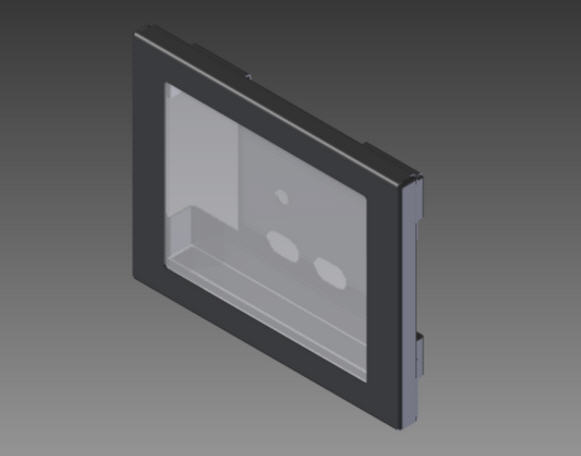

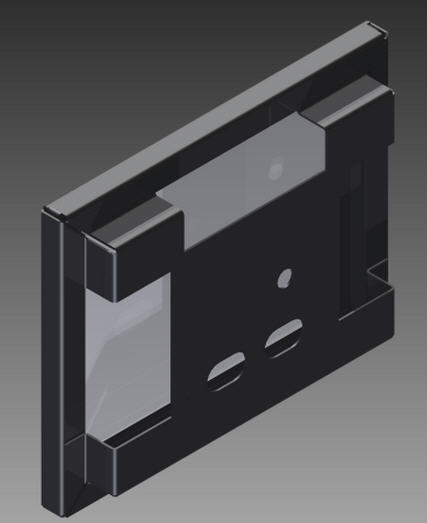

Digital Frame Product Development, Digital Picture Frame Design, Product Design for Digital Frame, Digital Screen

Written by Electronic Desgin Engineering Product DevelopmentDeveloping, Engineering and Manufacturing of Digital Frame

Since 2009 PAG Electronics is involved in sourcing, manufacturing and product development of digital screen for personnal and business use. Most of those items are used either in shop for advertising a product on shelf or for personnal use displaying pictures and video at home. With variable size, digital frame can vary from 1.5 inch diagonal size untill several dozen of inch (60 inch)

Face to the arrival of tablet on the market digital frame are on the competition but remain advantageous for their low price. Indeed, whereas tablet got a general purpose cpu and an oversized architecture for simple use, digital photo frame use only dedicated cpu/dsp for video and picture displaying. On this base, face to a tablet, the architecture is simplified and the cost lowered.

Digital Frame is not dead yet face to tablet as it is remains very simple to use, doesn't require application and never crash.

There are several possible applications with Digital Frame. Among the most common application:

- Digital Frame for promotional and sales environment / marketing

- Indoor consumer use

- Presentation

Electronic Product Development of Digital Frame with our Electronic Product Development Firm in China

Below, a few services we provide for digital photo frame and digital picture frame:

- Electronic design of Digital Frame

- Electronic development of Digital Frame

- Mechanical engineering of Digital Frame

- Firmware customization and user interface ergonomic optimization for Digital Frame

|

|

What special when developing and manufacturing Digital Frame

Pedometer are small device and have high requirement on spacing constraint, on this base mechanical design and engineering optimization is an important point to consider.

Pedometer electronic engineering also require audio and acoustic skills to be able to supply your customer with an excellent customer experience.

When considering product development of Digital Frame, choice of components is absolutely critical. Positioning, spacing and design related to motion engineering is also a critical point in product performance.

Some other mechanical elements such as cable, pin connector, quality of wire, and ergonomic are also to consider to make sure the robustness of your product. Finally the ergonomic and comfort are the first priority: design properly shape of part is more important than anything else and this to avoid compromising comfort of the user.

Finally, when considering engineering of Pedometer several industry area apply: acoustic, fluid physic, electronic, and mechanic.

Work with us to develop and manufacture your Digital Frame

We have confidence and capability to accompany your project of Digital Frame manufacturing and product development to make your project successful in a very short period of time. Our engineering team work closely with acoustic expert in order to optimize your product technically.

We have significant manufacturing experience for Digital Frame manufacturing.

Media Player Product Development and Electronics Design, Engineering, Video Player, PCB and Casing Development and Manufacturing in China

Written by Electronic Desgin Engineering Product DevelopmentMedia Player Product Development

Digital Signage Product Development, Electronics Design and Enginnering in China, Hardware, Firmware, PCB, Casing Development in China

Written by Electronic Desgin Engineering Product DevelopmentDigital Signage

Digital Signage Product Development content coming soon

Last operation of manufacturing remains to operate packaging. Once again PAG can deal with your packaging requirement

To insure a product to be without defect, strong and sharp quality control operations have to be performed before shipping goods.

PAG Electronics has deep understanding of what quality means. For this reason we are performing inspection during manufacturing process at different step of it:

IQC: Incoming Quality Control is performed on parts and components before they enter our warehouse

IPQC: In-Process Quality Control is performed during the assembly to make sure products being assemblied are according to the specification

FQC: Final Quality Control is performed randomly on some finished products at the end of the production

- electronics quality control

- electronics product inspection china

- IT product inspection china

- consumer electronics quality inspection china

- information technology quality control china

- during production inspection electronics china

- shenzhen inspection electronics

- quality inspection electronics china

- final inspection electronics china

- preshipment inspection electronics

Logistics may seems something easy on a first point of view but asking a customer being 20 000 kilometers away in chinese language and working with a shifted jetlag may make the management of logistics slightly more complex than just giving a phone a phone call to your post office.

To facilitate our customers life we can handle logistics between suppliers.

For those customer who would like to purchase components per batch and who would like to store them for using them order per order, PAG Electronics got capability to store your components, parts and goods safely in our warehouse until we get your requirement for shipping, dropshipping, dispatching and consolidation.

While parts are purchased from different supplier or distributors, in order to faciliate our customers life we got capabilities to manage and coordinate supply of components and parts from sub-suppliers ;

Supplier of PCB

Integrator to manufacture PCBA

Plastic / Metal Casing manufacrturer

Accessories vendor

Print and Packaging suppliers

PAG Electronics operate product assembly in its own western owned and managed assembly line in China.

More content coming soon.